Plastic Profiles

Boost the durability, efficiency, and aesthetics of your projects with our versatile plastic profiles, designed to meet demanding industrial and construction needs.

What are Plastic Profiles?

Plastic profiles are extruded components crafted to serve specific purposes like sealing, joining, and reinforcing. Made from durable, high-quality materials, these profiles provide cost-effective solutions for structural stability and protection across diverse industries.

Profile Types

Plastic profiles are available in a variety of designs, each catering to specific structural and functional needs. Below are the key profile types and their applications:

U Profiles

U profiles are ideal for edging polycarbonate sheets and other panels, preventing dust, moisture, and debris ingress. Commonly used in greenhouses, facades, and roofs, they enhance durability while maintaining a clean and professional appearance.

F Profiles

F profiles are designed to join panels seamlessly, ensuring a polished look and structural integrity. These profiles are widely used in construction projects requiring precise alignment and strong connections.

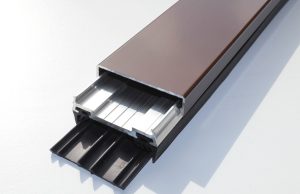

H Profiles

H profiles are perfect for joining two panels or sheets together. Known for their strength and durability, they are often used in partition walls, facades, and other structural applications requiring stability and long-lasting performance.

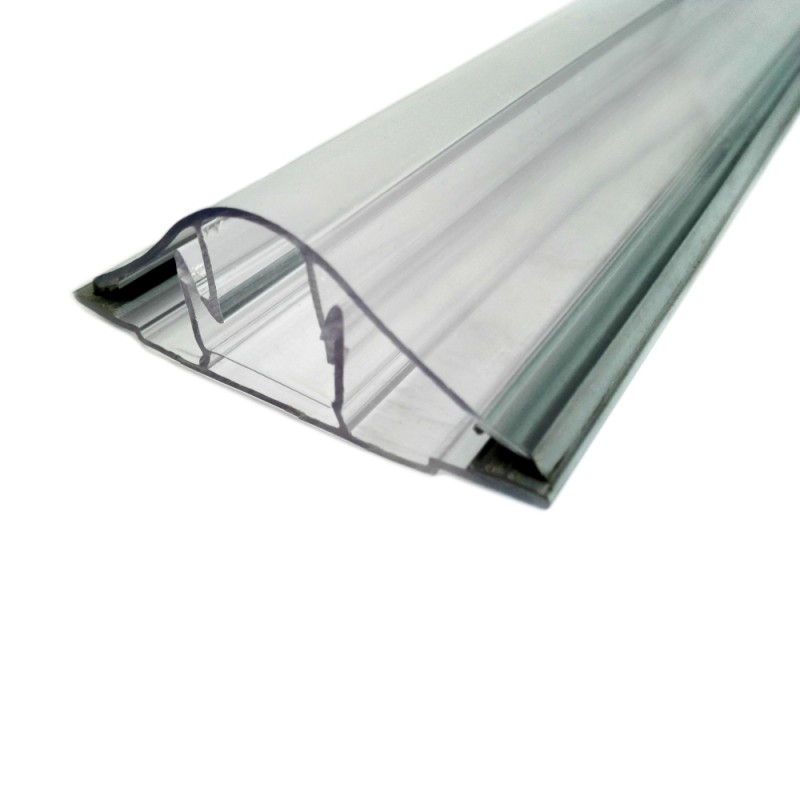

Ridge Profiles

Ridge profiles provide a secure, weatherproof seal along roof ridges, protecting against water leakage and environmental damage. They are essential in projects like greenhouses, sheds, and industrial buildings.

Corner Profiles

Corner profiles protect and reinforce panel edges, preventing damage from chipping or wear. Their robust design makes them ideal for high-traffic industrial settings or heavy-duty applications.

Universal Profiles

Universal profiles are versatile components used for various sealing and connecting purposes. Due to their adaptability, they can be utilized in different construction settings where standard profiles may not suffice. These profiles are ideal for sealing edges or joining panels in applications that require multipurpose, reliable solutions.

Why Choose Our Plastic Profiles?

Our premium plastic profiles offer reliable, versatile, and cost-effective solutions for construction, manufacturing, and automotive projects. Designed for durability and ease of installation, they are trusted by professionals to enhance project efficiency and performance.

You may also be interested

Need help? Contact us

For personalized assistance or inquiries, our dedicated team is here to help. We’re committed to providing you with exceptional support and guidance, ensuring that all your needs are met efficiently and professionally.