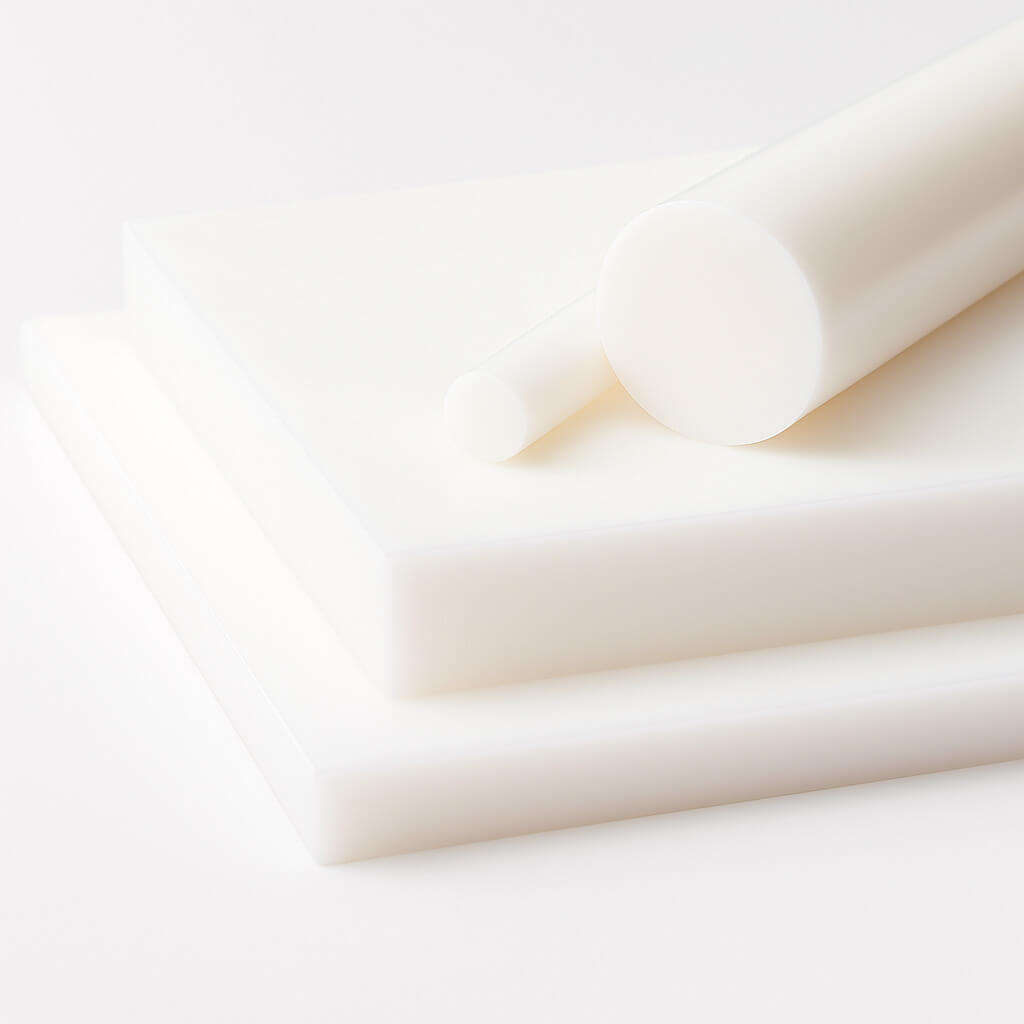

PTFE Plastic

High-performance PTFE sheets with outstanding chemical resistance, low friction, and wide thermal stability. Ideal for industrial, electrical, and food-grade use.

+1

+1

For Extreme Chemical, Thermal, and Mechanical Environments

PTFE plastic is a premium fluoropolymer material engineered for high-performance industrial applications. Known for its exceptional chemical resistance, non-stick surface, and wide operating temperature range, PTFE is the material of choice for sealing, insulating, and sliding components in the chemical, food, electrical, and medical sectors.

Key Features of PTFE Plastic

- Chemical Resistance: Inert to acids, alkalis, solvents, and oxidizers

- Extreme Temperature Range: Operates from –190 °C to +250 °C, effective up to 300 °C

- Low Friction & Non-Stick: Ideal for dynamic parts and easy-clean surfaces

- Food & Medical Safe: Compliant with EU Regulation 1935/2004

- Custom Reinforcement Available: Glass fiber, carbon, MoS₂, or coke-filled options

Available Forms and Dimensions

| Form | Thickness (mm) | Width (mm) | Length (mm) | Diameter (mm) |

|---|---|---|---|---|

| Sheet | 1–100 | 500 / 1000 / 1200 | 500 / 1000 / 1200 | – |

| Rod | – | – | 100 / 300 / 400 / 500 / 1000 | Ø 6–500 |

| Sleeve | – | – | 40 / 50 / 100 / 150 / 250 / 300 | Outer Ø: 40–450 Inner Ø: 15–350 |

| Tube | – | – | Up to 100,000 mm | Outer Ø: 3–25 Inner Ø: 2–22 |

| Film (Roll) | 0.5–3 | 1000 | 5000 – 50,000 mm | – |

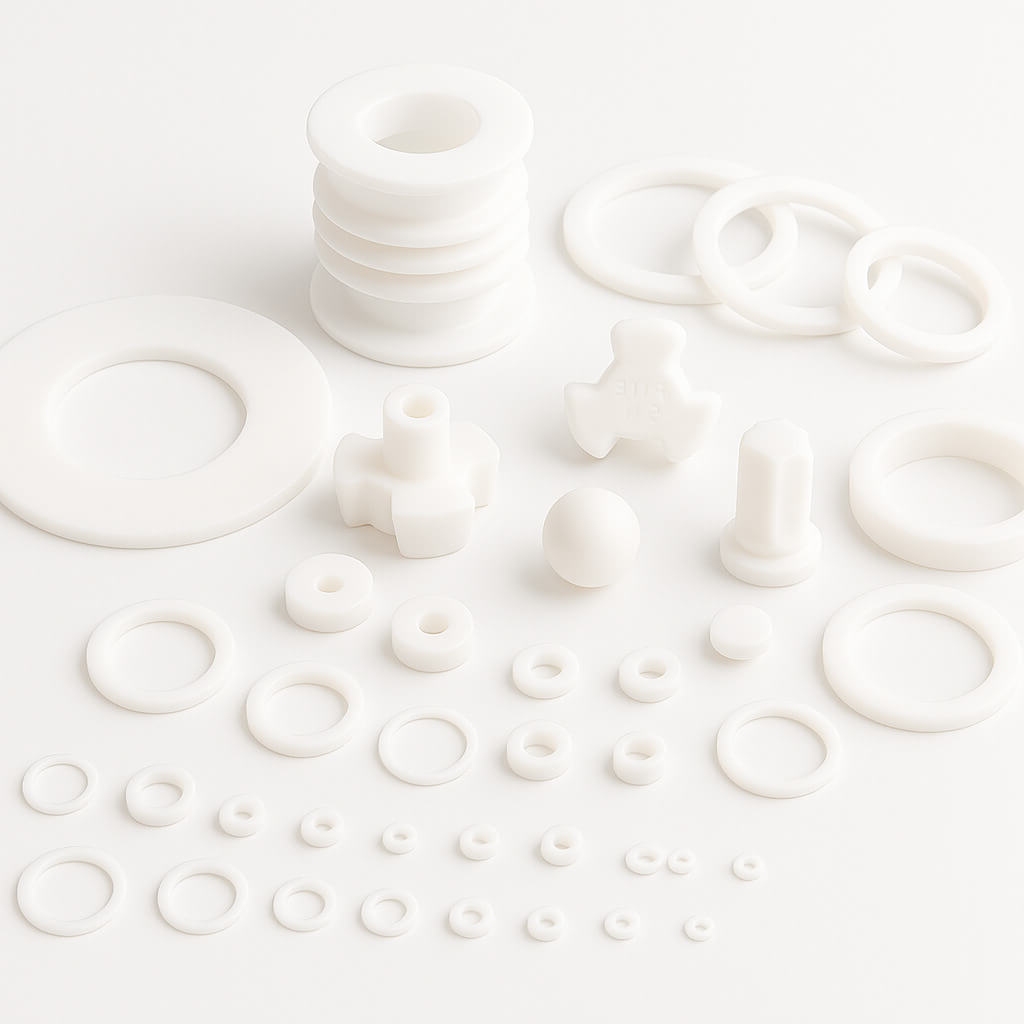

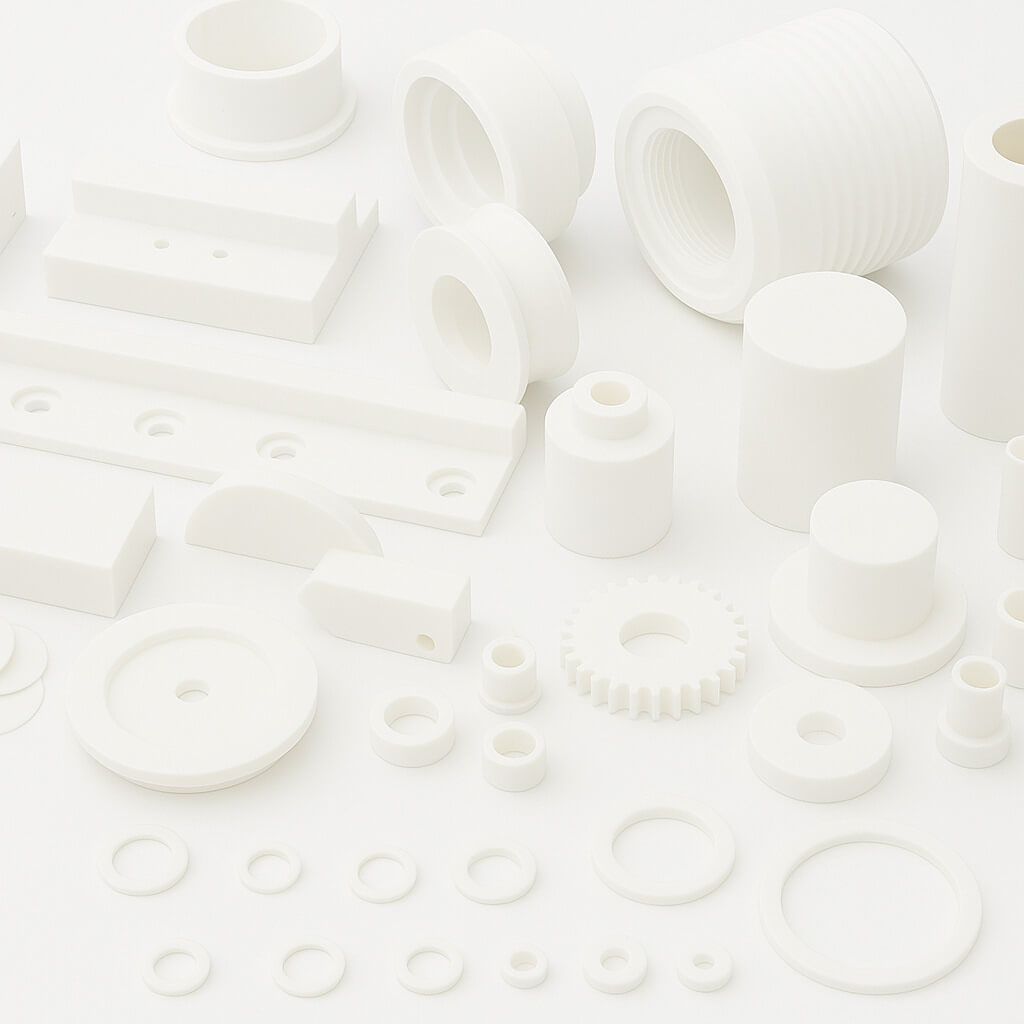

Applications of PTFE Plastic

- Chemical & Mechanical Industry: Gaskets, seals, pump parts, sliding plates

- Electrical: Dielectric barriers, terminal blocks, insulation parts (up to 200 °C)

- Food & Medical: Non-stick surfaces, biocompatible seals, pharma-grade components

Technical Properties

| Property | Value |

|---|---|

| Material | PTFE (Polytetrafluoroethylene) |

| Chemical Resistance | Excellent (acids, alkalis, solvents, oxidizers) |

| Density | 2.2 g/cm³ |

| Operating Temperature | -190 °C to +250 °C |

| Chemical Resistance Effective Up To | 300 °C |

| Dielectric Properties | Stable up to 200 °C |

| Friction Coefficient | Very low (~0.04) |

| Hydrophobicity | Completely hydrophobic |

| Biocompatibility | Physiologically and biologically safe |

| Food Contact Approved | Yes |

| Color | White (standard) |

| Available Modifications | With glass fiber, carbon, MoS₂, coke |

Need Custom Parts?

We offer custom machining of PTFE plastic components and production of technical plastic parts to your specifications.

You may also be interested

Need help? Contact us

For personalized assistance or inquiries, our dedicated team is here to help. We’re committed to providing you with exceptional support and guidance, ensuring that all your needs are met efficiently and professionally.