PET Polyethylene Terephthalate

A high-performance polyester plastic designed for precision and durability, ideal for demanding industrial and mechanical applications.

What is PET Polyethylene Terephthalate?

PET Polyethylene Terephthalate is a robust engineering plastic renowned for its exceptional mechanical strength, rigidity, and resistance to wear. This polyester material is a popular choice for applications requiring dimensional stability, high pressure resistance, and low friction. Its low moisture absorption ensures reliable performance and accuracy during manufacturing and in end-use environments.

Compared to alternatives like POM (polyacetal) or PA (nylon), PET Polyethylene Terephthalate stands out with its ability to withstand higher operating temperatures and its superior resistance to acids. While not impact-resistant at low temperatures and unsuitable for hot water or steam (above +60°C), PET excels in dry and chemically stable environments, making it indispensable in various industries.

Applications of PET Polyethylene Terephthalate

Mechanical Industry

- Precision components such as gears, bearings, and sliding bushings.

- High-pressure parts, including rollers, guiding elements, and wind turbine components.

- Reliable and long-lasting components for industrial machinery.

Medical Equipment Manufacturing

- Stable and precise components for medical devices and instruments.

Electrical and Electronics

- Plugs, connectors, and socket parts for electrical systems.

- Insulating components benefiting from PET’s outstanding dielectric properties.

Food Industry

- FDA-compliant parts for dough dispensers, measuring devices, and other food-handling equipment.

General Industrial Use

- Rings, valves, levers, pump components, dosing systems, and pistons for high-stress environments.

Key Features of PET Polyethylene Terephthalate

Characteristics and Benefits

- Dimensional Stability: Exceptional resistance to thermal expansion and moisture, ensuring accuracy and reliability.

- Mechanical Strength: High hardness, stiffness, and durability to withstand mechanical stress and pressure.

- Low Friction: Excellent wear resistance for applications with continuous motion or high loads.

- Chemical Resistance: Resistant to oils, fuels, acetone, low-concentration acids, and water up to +40°C.

- Ease of Machining: Easily processed into precise shapes and sizes, compatible with performance-enhancing additives like PTFE.

- Dielectric Properties: Excellent insulating capabilities for electrical applications.

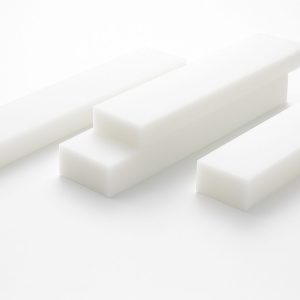

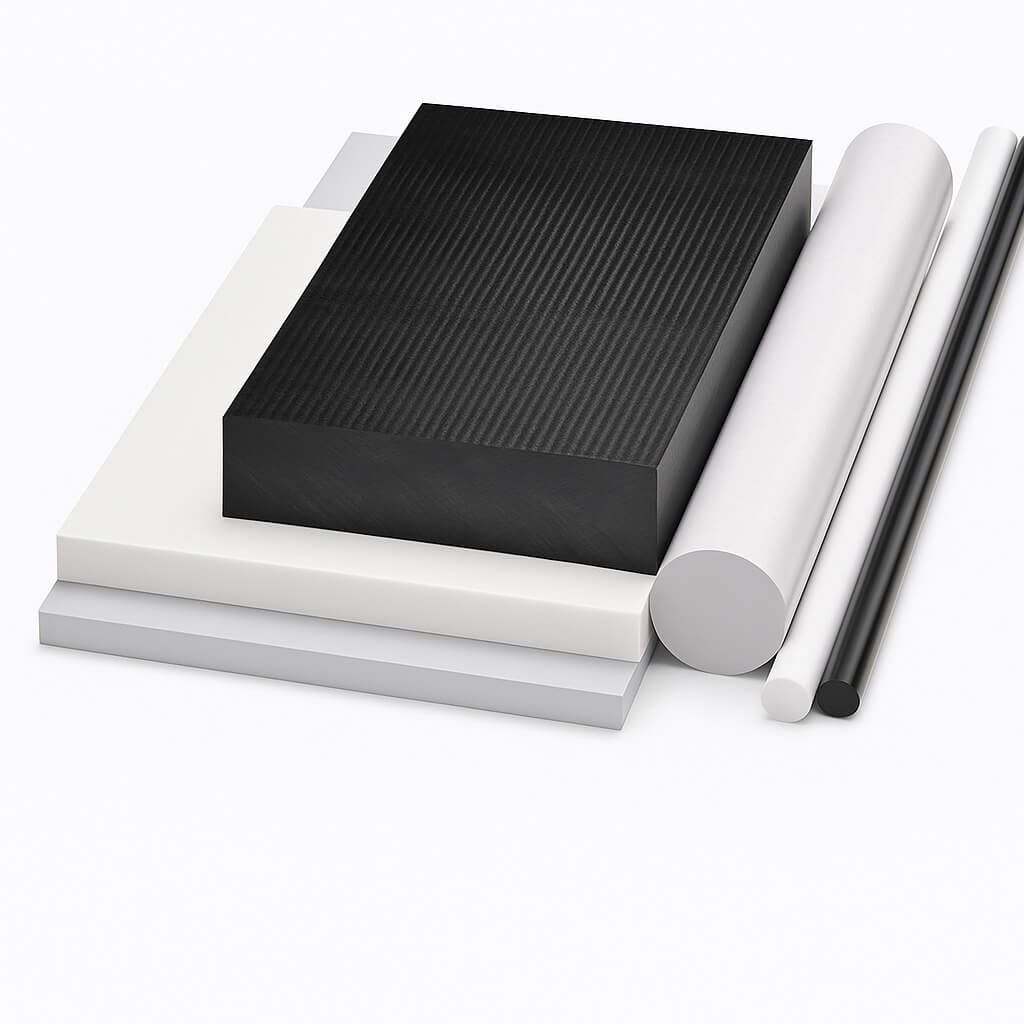

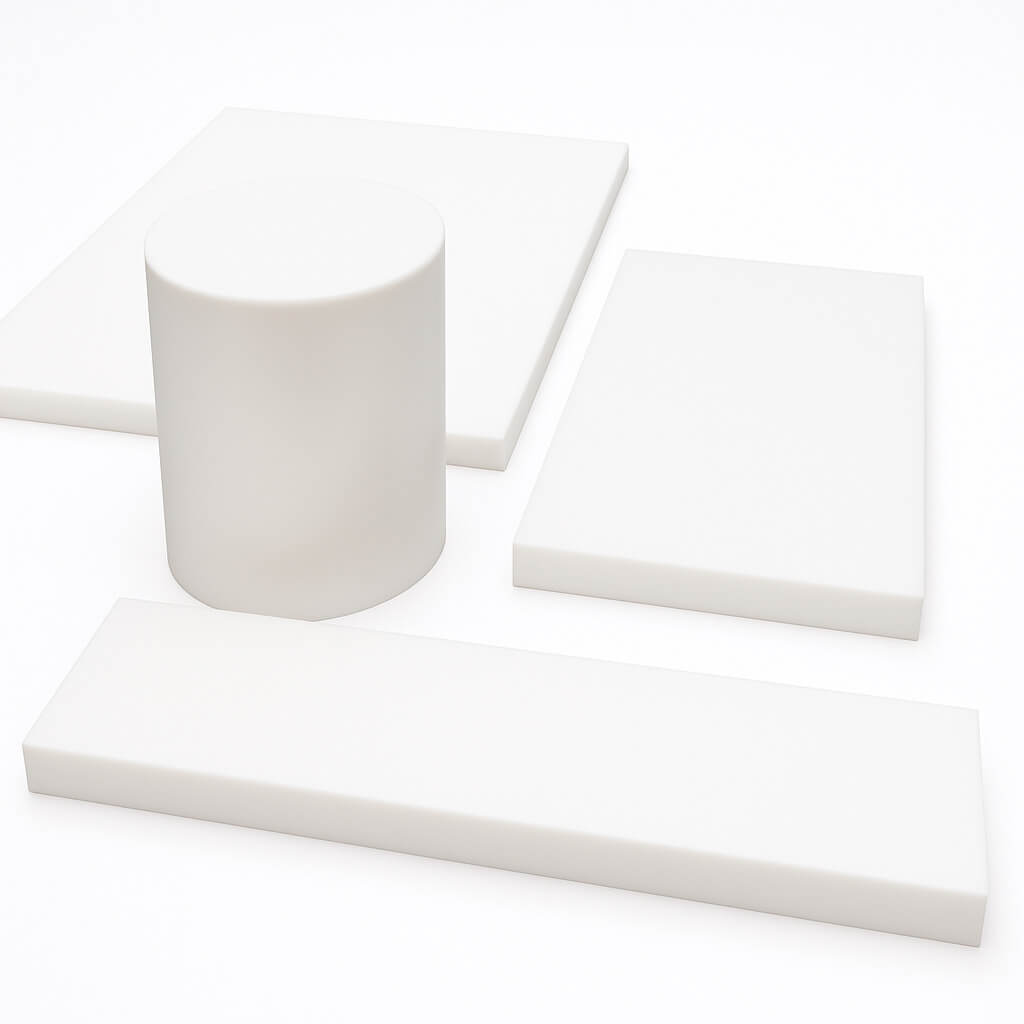

Dimensions and Availability

Sheets

- Thickness: 2–100 mm

- Width: 610, 620, or 1000 mm

- Length: 2000 or 3000 mm

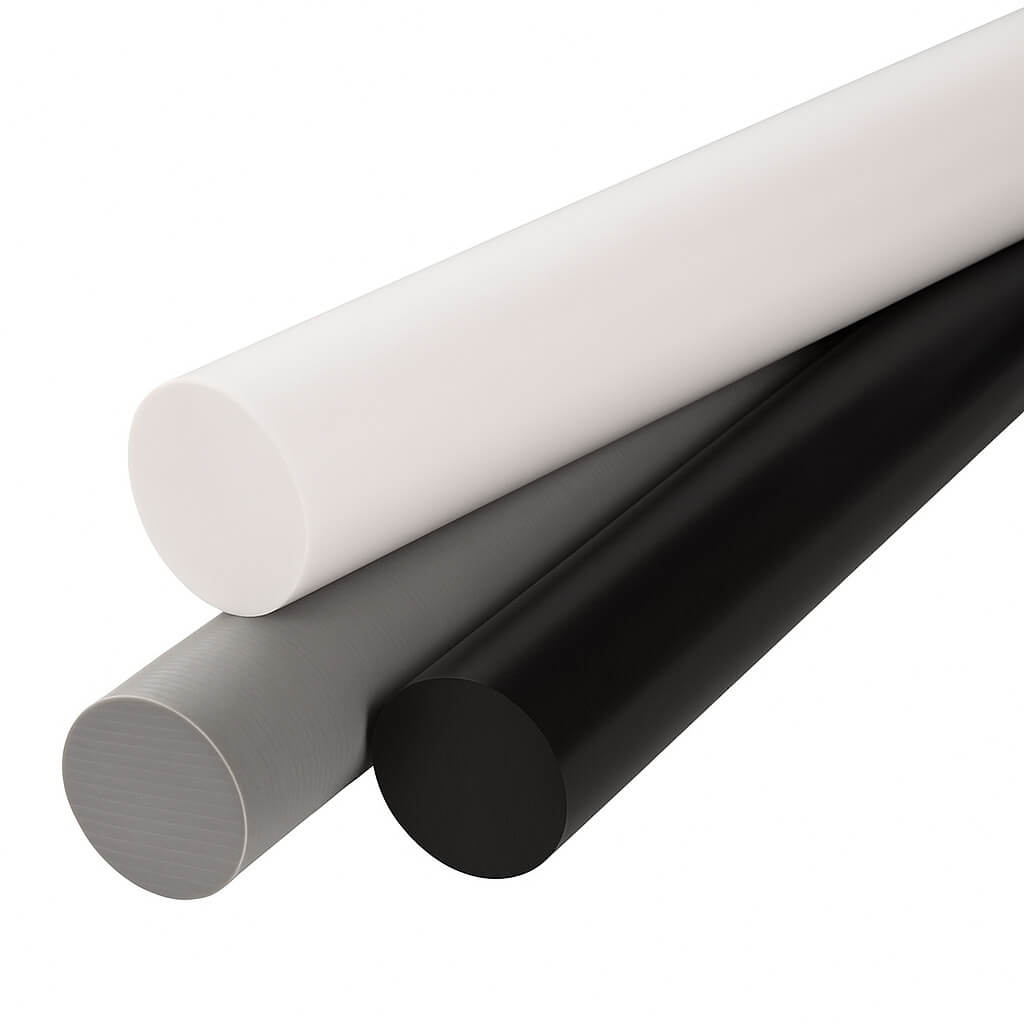

Rods

- Length: 1000 or 3000 mm

- Diameter: 10–200 mm

PET Polyethylene Terephthalate offers unmatched durability, precision, and adaptability across diverse industries. Whether used in precision manufacturing, electrical assemblies, or food-safe applications, this versatile material delivers consistent performance and long-term reliability, making it the preferred choice for industrial professionals worldwide.

You may also be interested

Need help? Contact us

For personalized assistance or inquiries, our dedicated team is here to help. We’re committed to providing you with exceptional support and guidance, ensuring that all your needs are met efficiently and professionally.