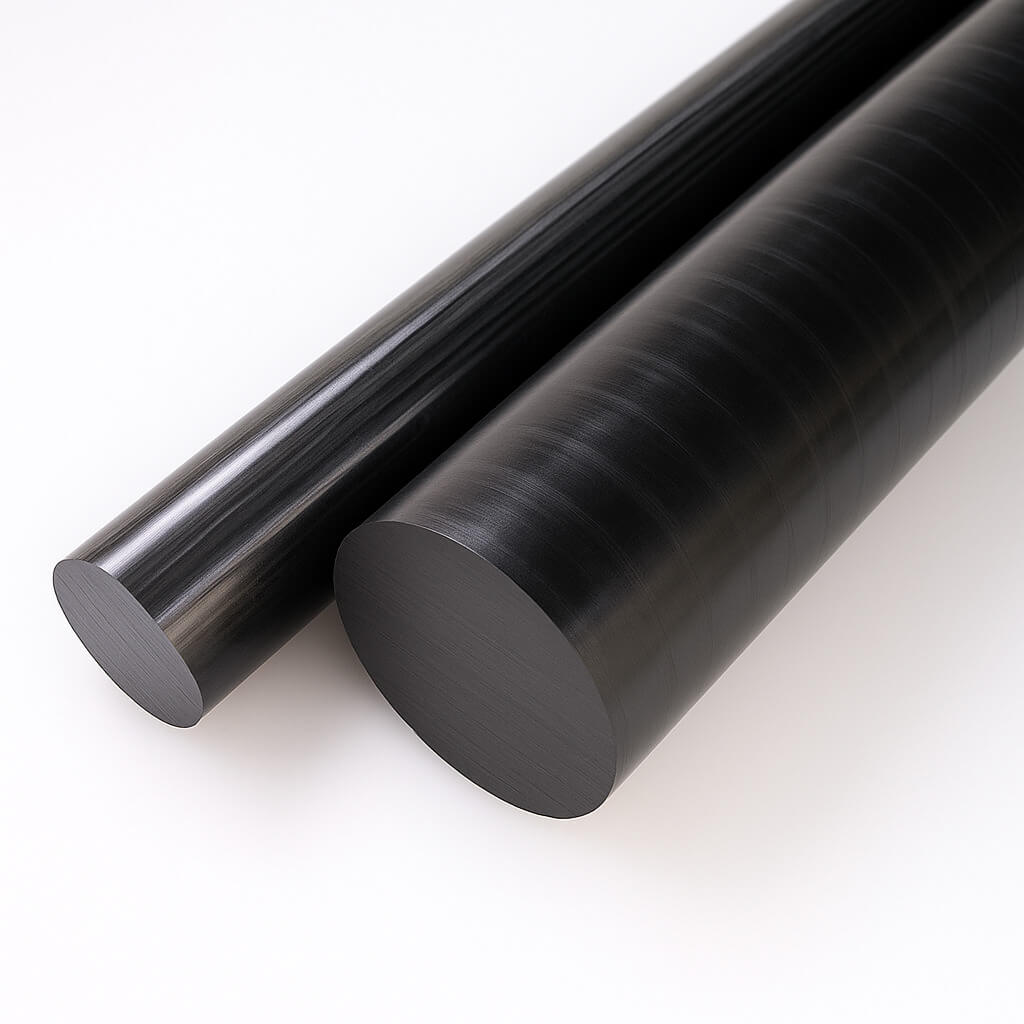

POM Plastic

Durable and precise POM plastic (Polyacetal) offers high stiffness, low friction, and excellent wear resistance. Ideal for food, automotive, and industrial use.

+1

+1

High-Precision Engineering Material for Demanding Applications

POM plastic (Polyoxymethylene), also known as acetal or polyacetal, is a high-performance thermoplastic engineered for precision parts and long-term durability. Available in copolymer (POM-C) and homopolymer (POM-H) variants, it offers excellent mechanical strength, wear resistance, and low moisture absorption.

Key Features of POM Plastic

- Food Grade Approved: Suitable for applications involving direct food contact (EU Regulation 1935/2004).

- Dimensional Stability: Low water absorption, maintains shape in humid environments.

- High Mechanical Performance: Strong, rigid, and impact-resistant for precision parts.

- Wear and Chemical Resistance: Withstands friction, fuels, and a wide range of chemicals.

- Alternative material: In many areas, polyacetal (POM) can replace polyamide (PA).

Available Forms and Dimensions

| Form | Thickness (mm) | Width (mm) | Length (mm) | Diameter Ø (mm) |

|---|---|---|---|---|

| Sheet | 1–200 | 620 / 1000 / 1250 | 1000 / 2000 / 3000 | – |

| Rod | – | – | 1000 / 2000 / 3000 | 6–500 (POM-C) 30-90 (POM-H) |

| Sleeve | – | – | 1000 / 2000 / 3000 | Outer: 20–500 Inner: 10–375 |

| Film | 0.3 – 1 | 1000 / 2000 | Roll (0,3 mm) | – |

Applications of POM Polyacetal

- Manufacturing: Ideal for gears, bushings, and pump components. High stiffness and wear resistance make it suitable for industrial applications requiring precision and long service life.

- Food Processing: Complies with EU food contact regulations. Used for parts in conveyor systems, packaging machines, and cutting tools. Easy to clean and highly durable.

- Automotive: Resistant to fuels, oils, and temperature fluctuations. Commonly used in fuel systems, valves, and connectors due to its dimensional stability and chemical resistance.

Technical Properties

| Property | Value POM-C (Copolymer) | Value POM-H (Homopolymer) |

|---|---|---|

| Density | 1.43 g/cm³ | 1.43 g/cm³ |

| Operating Temperature | -50 °C to +105 °C | -50 °C to +90 °C |

| Water Absorption | 0.3% | 0.3% |

| EU Food Compliance | Yes | Yes |

| Colour | Natural (white), black, others (on request) | Natural (white), black, others (on request) |

Need Custom Parts?

We offer custom machining of POM plastic components and production of technical plastic parts to your specifications.

You may also be interested

Need help? Contact us

For personalized assistance or inquiries, our dedicated team is here to help. We’re committed to providing you with exceptional support and guidance, ensuring that all your needs are met efficiently and professionally.