Tray washers

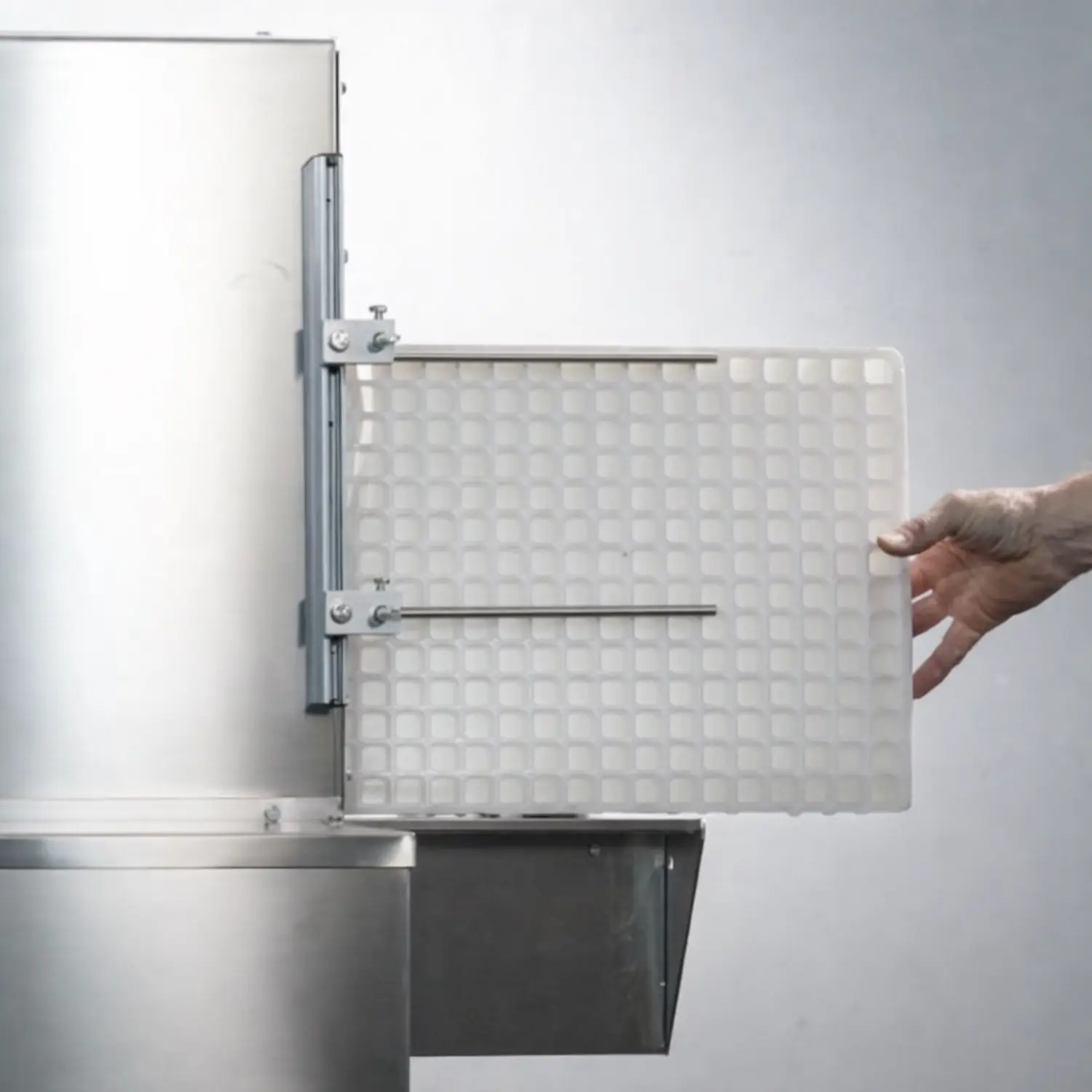

Industrial tray washers are essential components in modern nursery and greenhouse automation, designed to clean and sanitize cultivation containers between production cycles. These systems ensure that polystyrene, rigid plastic, and thermoformed trays are thoroughly decontaminated to prevent cross-contamination and maintain high phytosanitary standards.

System Overview

Modern washing systems range from compact, manual-load units to fully automated, high-capacity lines integrated into a facility’s logistics chain. These machines utilize a combination of high-pressure fixed and rotating nozzles to remove substrate residue and pathogens, often featuring modular configurations that include rinsing, disinfection, and drying stages.

By automating the sanitation process, these systems provide a predictable and repeatable cleaning result that manual washing cannot achieve. This reliability is critical for large-scale operations where consistent tray hygiene directly impacts seedling health and overall crop success.

Key Benefits for Professional Use

Operational Efficiency: Supports high-throughput environments with capacities ranging from 200 to over 600 trays per hour.

Resource Conservation: Advanced water recirculation and micrometric filtration systems significantly reduce water consumption and allow for extended operation between tank changes.

Phytosanitary Control: Integrated disinfection modules—including chemical dosing or UV sterilization—ensure trays meet strict biosecurity protocols.

System Versatility: Modular designs and adjustable rails allow for the processing of various container dimensions, from seed trays to heavy-duty crates.

Reduced Labor Dependency: Automation of the cleaning cycle minimizes manual handling and reallocates labor to high-value production tasks.

Durability: Construction using high-grade stainless steel and premium industrial components ensures longevity in humid greenhouse environments.

Typical Applications

Commercial Nursery Propagation: Regular sanitation of seeding trays to ensure a sterile environment for young plant development.

Automated Greenhouse Logistics: Cleaning and drying of internal transport crates and shuttle trays used in benching systems.

Vegetable and Ornamental Crop Production: Standardized washing of reusable plug trays to prevent the spread of soil-borne diseases.

Vertical Farming Systems: Integration into closed-loop cultivation cycles where container hygiene is critical for multi-layer environments.

Technical Consultation and Project Support

Selecting the appropriate tray washers requires a detailed analysis of your facility’s throughput requirements, water treatment capabilities, and existing automation footprint. We assist production managers in evaluating system integration and modular scalability to ensure the cleaning line aligns with specific operational workflows. Early-stage technical dialogue is encouraged to determine the optimal configuration for your site layout and container specifications.

Need help? Contact us

For personalized assistance or inquiries, our dedicated team is here to help. We’re committed to providing you with exceptional support and guidance, ensuring that all your needs are met efficiently and professionally.