Fiberglass Fabrics and Nonwoven Materials

Fiberglass fabrics and nonwoven materials provide superior thermal insulation, strength, and durability for various industrial applications.

What is Fiberglass Fabric and Nonwoven Material?

Fiberglass fabrics and nonwoven materials are made from E-glass (aluminoborosilicate) fibers, designed for use in a wide range of industries requiring thermal insulation and mechanical strength. These materials are woven or nonwoven and come in various densities, making them highly versatile. Commonly used in industries like automotive, marine, aerospace, and industrial manufacturing, fiberglass fabrics are crucial in producing composite materials, ensuring high durability, flexibility, and resistance to extreme conditions.

Applications of Fiberglass Fabrics and Nonwoven Materials

Automotive and Marine Industry

Fiberglass fabrics are frequently used in the production of car body parts, boat hulls, and other structural components. These materials provide excellent strength-to-weight ratios, ensuring that vehicles and boats maintain durability while staying lightweight. Additionally, fiberglass offers high resistance to corrosion, which is essential for vehicles exposed to harsh environments, such as saltwater in marine applications.

Aerospace Industry

In the aerospace industry, fiberglass is a key component in creating lightweight yet strong parts for aircraft and other flying vehicles. Its ability to withstand extreme temperatures without expanding or contracting makes it ideal for high-altitude flight, where temperature variations are common.

Industrial Manufacturing

Fiberglass fabrics play a significant role in manufacturing chemical tanks, heat shields, and cleaning equipment. Their chemical resistance and flame-retardant properties make them indispensable for industrial environments where safety and durability are critical.

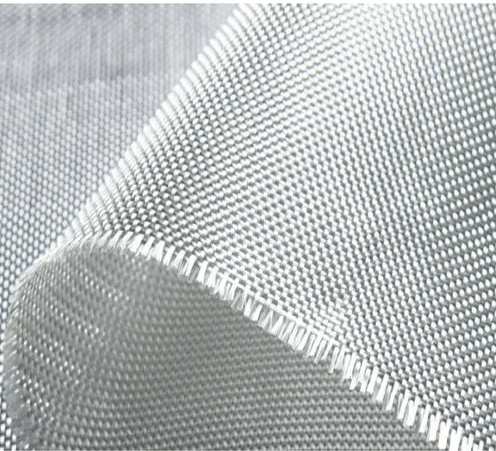

Key Features of Fiberglass Fabrics and Nonwoven Materials

High Stability

Fiberglass is a highly stable engineering material, retaining its shape even under extreme temperature variations from -200°C to +550°C. With a maximum elongation of 4.8%, it maintains its integrity in demanding applications.

Moisture and Chemical Resistance

Fiberglass fabrics do not absorb moisture, nor are they affected by water, making them ideal for applications that require long-term durability in wet or chemically aggressive environments.

Fire Resistance

Fiberglass materials are inherently non-combustible and retain 25% of their original strength at 540°C, ensuring excellent fire resistance, which is essential in industrial safety applications.

Anti-Corrosive Properties

With superior anti-corrosive and dielectric properties, fiberglass fabrics resist degradation when exposed to harsh chemicals, ensuring longevity and reliability in industrial processes.

Excellent Strength-to-Weight Ratio

Fiberglass materials offer high strength while maintaining minimal weight, making them highly efficient for use in various applications where material performance and weight are critical factors.

You may also be interested

Need help? Contact us

For personalized assistance or inquiries, our dedicated team is here to help. We’re committed to providing you with exceptional support and guidance, ensuring that all your needs are met efficiently and professionally.