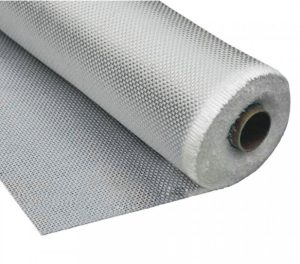

Fiberglass Mesh Coated with PTFE

Fiberglass mesh coated with PTFE provides exceptional heat resistance and moisture control, making it an ideal choice for various industrial drying processes.

What is Fiberglass Mesh Coated with PTFE?

Fiberglass mesh coated with PTFE is a high-performance material used in a wide range of industrial applications. It is lightweight, economical, and designed to optimize moisture removal in drying processes. The PTFE coating enhances durability and offers a non-stick surface, making the mesh particularly effective in high-temperature environments such as ultraviolet (UV) and infrared (IR) dryers. This mesh is frequently utilized for product transportation in systems that require efficient air distribution, helping to minimize drying times.

Applications of Fiberglass Mesh Coated with PTFE

Printing Industry Applications

In the printing industry, fiberglass mesh coated with PTFE plays a crucial role in drying printed materials such as window displays, t-shirts, glass, and mass-produced paper. Its efficient heat distribution in UV, IR, or hot-air dryers ensures rapid drying, helping to maintain the quality and finish of printed products.

Food Processing Applications

In food processing, this PTFE-coated fiberglass mesh is used for transporting products through high-efficiency drying systems. The non-stick PTFE surface ensures that food products do not adhere to the mesh, making it easy to clean and maintain, while also ensuring that it meets food-grade requirements.

Textile and Nonwoven Fabric Applications

The mesh is also widely used in the textile industry for drying products like garments, carpets, and nonwoven fabrics. Its lightweight and durable design helps reduce drying times while ensuring consistent product quality, making it a preferred solution in large-scale textile manufacturing.

Key Features of Fiberglass Mesh Coated with PTFE

Characteristics and Benefits:

- Lightweight and Economical. Compared to wire alternatives, this mesh is lighter and more cost-effective, reducing operational costs and downtime while enhancing overall efficiency.

- High Temperature Resistance. The fiberglass mesh withstands operating temperatures from -73°C to +260°C, making it suitable for a wide range of industrial drying applications.

- Chemically Inert. The PTFE coating provides chemical resistance and ensures the mesh remains unaffected by UV, IR, microwave, and radio frequencies, making it versatile for different industries.

- Food-Grade Compliance. This mesh is USFDA-approved, ensuring it meets food safety standards, making it an ideal choice for use in food processing environments.

- Non-Stick Surface. The PTFE coating creates a non-stick surface, making the mesh easy to clean, preventing residue buildup during drying processes.

You may also be interested

Need help? Contact us

For personalized assistance or inquiries, our dedicated team is here to help. We’re committed to providing you with exceptional support and guidance, ensuring that all your needs are met efficiently and professionally.