PP Polypropylene

PP Polypropylene is a durable plastic known for its outstanding chemical resistance to alkalis and acids, making it ideal for various industrial applications, including food and chemical industries.

What is PP Polypropylene?

PP (Polypropylene) is a high-performance thermoplastic commonly used in industries requiring chemical resistance and mechanical strength. Compared to PE-HD (PE 300), it is slightly stiffer and harder. Due to its superior resistance to organic compounds and chemicals, polypropylene is widely utilized in producing containers, wastewater treatment systems, fish farming tanks, and outdoor pools. It’s also extensively used in hot tub manufacturing, with color options including blue. PP is easy to process, allowing for cutting, milling, bending, and drilling. However, due to its chemical inertness, bonding is difficult, and welding is the preferred joining method.

Applications of PP Polypropylene

Food Industry

PP is extensively used in the food industry to manufacture containers and storage tanks for food processing and packaging, thanks to its non-reactive nature and compliance with safety standards.

Chemical Industry

Its high resistance to acids and alkalis makes PP an ideal material for chemical storage tanks, pipelines, and wastewater treatment systems, ensuring durability in aggressive environments.

Aquaculture

PP is a preferred material for fish farming reservoirs and tanks due to its excellent water resistance and structural rigidity, ensuring long-term use in aquatic environments.

Recreational Products

Due to its durability and flexibility, PP is commonly used in manufacturing hot tubs and outdoor pools. It can be easily thermoformed and customized in various shapes and colors.

Key Features of PP Polypropylene

Characteristics and Benefits

- High Chemical Resistance:

PP resists a wide range of chemicals, including acids and alkalis, ensuring longevity in harsh environments. - Durability:

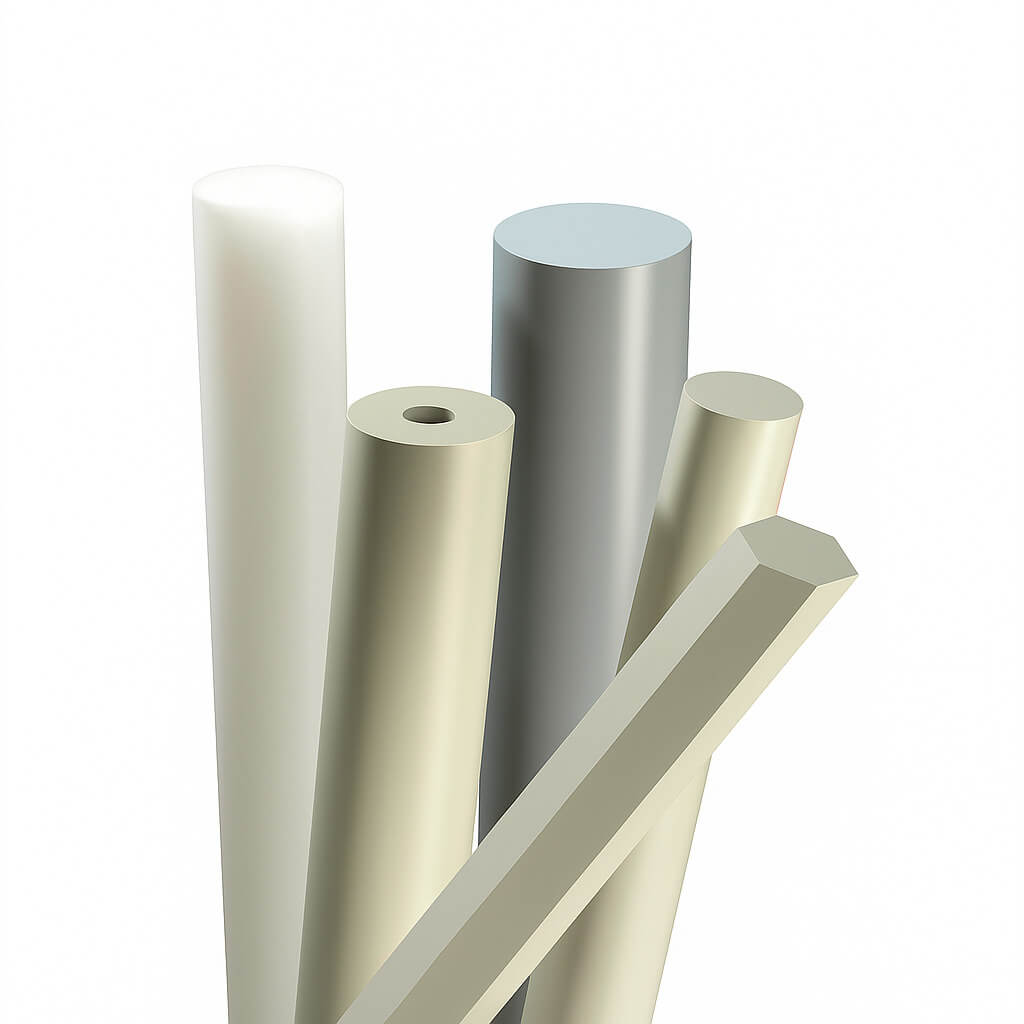

With its superior stiffness and hardness compared to other plastics, PP offers excellent structural integrity. - Versatility:

Available in various forms such as sheets, rods, and welding rods, PP can be used across multiple industries. - Wide Temperature Range:

Depending on the type, PP can withstand temperatures from -20°C to +100°C, making it suitable for diverse applications. - Easy to Process:

PP can be easily cut, drilled, and thermoformed, offering convenience in manufacturing custom shapes and designs.

Types of PP Polypropylene

PP-H AlphaPlus (Homopolymer)

- Density: 0.91 g/cm³

- Working Temperature: 0°C to +100°C

- Forms: Sheets, rods, welding rods

- Colors: White, light gray (RAL 7032)

Recommendation: PP-H is suitable for high-temperature applications and is available in custom-cut sizes for convenience.

PP-C (Copolymer)

- Density: 0.91 g/cm³

- Working Temperature: -20°C to +80°C

- Forms: Sheets, welding rods, rolled sheets

- Colors: White, blue, light gray (RAL 7032)

Recommendation: PP-C is ideal for lower-temperature environments due to its slightly higher elasticity compared to PP-H.

Specialized Types of PP Polypropylene

Orthopedic PP Plastics

- Types: SIMOLIFE PP, SIMOLIFE PP-C

- Application: Used in the production of prosthetics and orthopedic devices.

- Features: Highly thermoformable, available in transparent and flesh tones.

- Form: Sheets

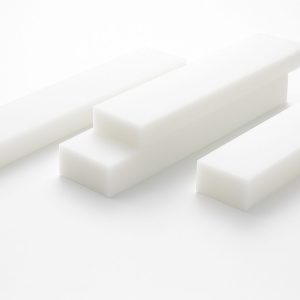

Cutting Boards PP

- Types: SIMONA® frisylen® JN 480, frisylen® SP, frisylen® BNL, frisylen® XL 75

- Application: Used for manufacturing cutting boards of various hardness, primarily for cutting artificial and natural leather.

You may also be interested

Need help? Contact us

For personalized assistance or inquiries, our dedicated team is here to help. We’re committed to providing you with exceptional support and guidance, ensuring that all your needs are met efficiently and professionally.